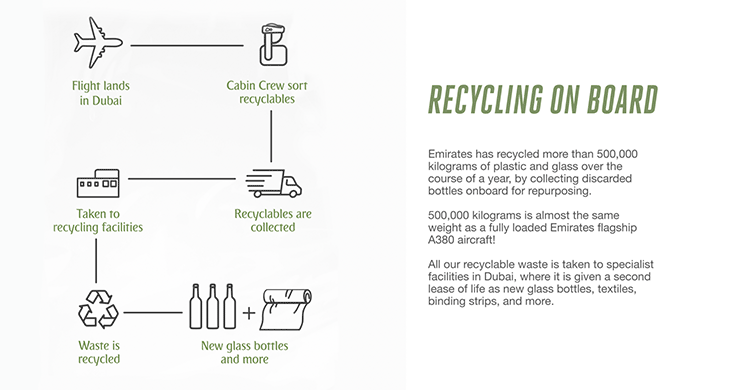

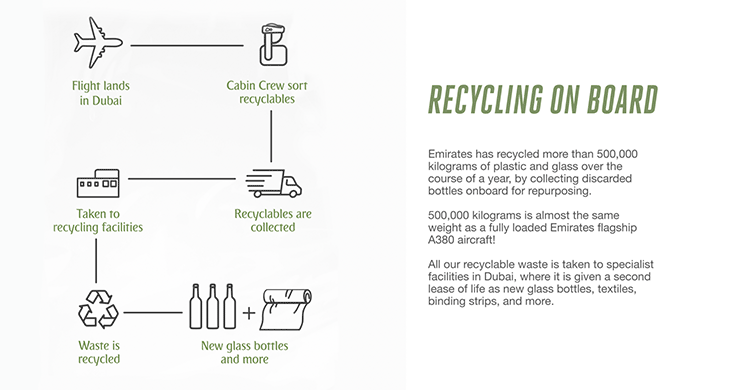

Emirates has revealed that it recycled more than 500,000kg of plastic and glass during 2022, weighing nearly as much as its flagship A380 aircraft when fully loaded. The recyclables were...

Read More

Aircraft recycling company, Aircraft Solutions USA is to establish a new US$100 million facility at North Carolina’s Global TransPark to recycle aircraft parts and materials. In phase one of the…