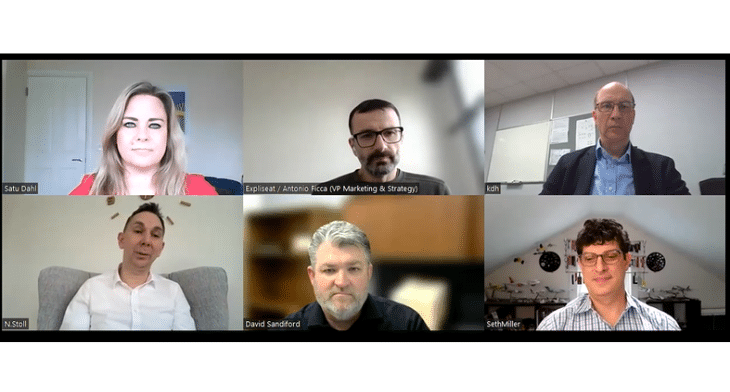

Ahead of this year’s Aircraft Interiors Expo (AIX) taking place in Hamburg from 28-30 May, the event’s organisers got together with Inflight Editor Satu Dahl and a great range of industry professionals for its insightful sustainability-focused roundtable discussion, Net Zero’s Impact on the Cabin of the Future.

The roundtable discussion, which was moderated by Satu Dahl, Editor of Inflight, took a deep dive into the aircraft interiors and the ways they can contribute to aviation’s sustainability targets, also examining the net zero targets for aviation. The session featured a fantastic panel, with a great range of companies represented from the industry.

This expert line up of speakers included Nils Stoll, CEO of Krüger Aviation, a technologically advanced company which has several business units specialising on component services, materials advice and supply and technical support as well as an innovation centre; Seth Miller, Founder and Editor-in-Chief of PaxExAero which delivers detailed insight into the airline passenger experience; Antonio Ficca, Vice President of Marketing at aircraft seating manufacturer Expliseat; Karl Hewson, Director of Technology and Development at aircraft interior materials company Zotefoams; and David Sandiford, Manager Aviation – Transportation Accounts Department – Enterprise Accounts and International at Mohawk Group which manufactures flooring products for aviation.

Below are just a small number of the highlights from the roundtable discussion, with plenty more featured in the full-length video recording which is available here.

Working together for a greener future

Naturally, there were several different ways the roundtable speakers had noticed global net zero targets impacting the aircraft interiors sector. Nils Stoll pointed out that a zero-emissions aircraft cabin is very much possible; however, he noted that companies have to work together to make it a reality. “Krüger Aviation, as one small mid-size company in Germany, can’t make that happen on its own. This is a total industry target that we have to achieve together and we need to show the world that the aviation industry has some of the most promising solutions if we want save the planet.”

David Sandiford explained that Mohawk has done a good job in terms of using sustainable material in the manufacturing. “We are beyond carbon neutral, meaning that now all of our commercial products, whether it is commercial flooring for the building industry or whether it is for aviation industry, are beyond carbon neutral. And we’re one of the few companies that have signed the climate pledge with the target of being carbon neutral by 2040 in terms of our manufacturing processes.

“Now, the decision makers in the industry are increasingly wanting to understand what the sustainability attributes of the products are, which then becomes a challenge because there’s no equal measurement, whether it’s an EPD or any other tools that those decision makers are using to evaluate each product equally.”

Karl Hewson, Director of Technology and Development, Zotefoams noted: “You’ve got to accept that there is a carbon premium. We’re all prepared to pay for certain things such as safety, right? And neutrality isn’t really neutrality. The energy has to come from somewhere. The materials have to come from somewhere. And while we can offset to some extent, there is still going to be a choice that something’s going to need a bigger offset than something else, right?

“You need the lightest material possible to minimise the fuel burn. And that’s always been our focus. And it’s not just about our material, the foams that are used in there, it’s about other materials that are used with them. So, for example, if you can make something that friction fits rather than needing an adhesive, it’s not just about the lightweight plastic being a foam, it’s about eliminating other materials.

“Other innovations that we’ve been pushed onto are things like mono materials. Can you make all of the materials the same? The end of the 25-year product life seems a long way away. At the end of the 25 years, it’s all the same material. We don’t need to sort it out. We know it can go back into one recycle stream. So there are a number of things, design flexibility, design innovation that all can contribute, including light-weighting, which includes reducing the weight of plastics by foaming that reduce fuel burn.”

Antonio Ficca of Expliseat agreed. “The number one priority for anybody should be to reduce weight. Before anything else, reduce weight. Expliseat founders that came a long time before me knew that, and figured out that if you want to reduce weight without compromising on comfort or robustness, which are extremely important to the airlines, or other factors, then you have to innovate.”

“There are other ways of recycling your own materials. Some airlines do that, Expliseat is not the only one. We offer a programme to our customers to take the seats back at the end of their lives. And we would recommission the seats into additional seat components. So, we actually create this circular economy environment that enables us to A, deliver lightweight product, and B, recycle the material.”

Balancing act

When discussing how the industry can balance the need for sustainability in the cabin with ensuring a comfortable and enjoyable passenger experience, Seth Miller shared his thoughts on the dilemma: “It is possible to at least, you know, maintain comfort. But I do think there’s a challenge in the industry certainly having seen cabin densification and sort of padding, we’ll say removed, right? The cushions are thinner now, are they as comfortable as they were? Maybe, maybe not, but they’re definitely thinner than they used to be. And passengers who’ve been flying for a while notice that sort of thing. And any change is hard. So if you have a, you know, step change, the significant changes that are needed, implementing any of those is likely to bring some blowback from consumers who are not convinced that it’s going to be as good as it was before.

“Change is hard. And so, that is definitely a challenge we face as an industry, obviously doing it for good reasons mostly. But that is a challenge that we face. I think one of the other interesting things, and we talk about just sort of overall weight and things in the cabin and the passenger experience, part of it’s the shape of the seat, but also, how are we entertaining passengers? And how are we dealing with some of those other sort of bits and bobs that get attached on, whether it’s cabin monuments or tray tables and cup holders, things like that. So it really is, you know, end-to-end experience that becomes challenging.

“But there are a lot of different places to look at where can we, you know, shave a little bit here and there, and is it still as comfortable or as good? I mean, a smaller lavatory is lighter, but if everybody going in and washing their hands ends up splashing water all over themselves, they’re not going to be happy, are they?”

When it comes to untapped opportunities and areas for improvement, are there any that we could look into to further enhance the sustainability of cabin design and the passenger experience? David Sandiford shared his thoughts: “Well, I would go back to what we see on the commercial design and development process for buildings, whether it is a lead certified building, you know, the industry has more of a standard go-to market strategy for whether it is the carpet that goes on the floor, the walls, or the ceiling tiles, all of that comes under general certifications.

“Whereas within the airline industry, at least the cabin interior, we don’t have that same type of standardisation. And I think that’s going to be a challenge, the understanding what it takes to get to that type of standardisation. You know, where you could imagine this is a lead certified cabin interior, right? Well then at that point in time, once you have that standardisation, it’s much easier to educate the flying public and then they can make an educated decision if they want to have a value proposition on flying with this airline because they have a lead certified cabin.”

Seth Miller, however, noted he is sceptical of this: “I’m not sure if I’m right or you’re right, but I’m sceptical of that. Passengers have been given the option to pay up a little for offset or sustainable aviation fuel depending on the airline, and almost universally choose not to. And we’ve known that the statistics are not great on that uptake. So, maybe a passenger might choose to fly with an airline, assuming the price is the same. But then we’re back to what’s the cost of this? And can the airline find a way to either push that innovation and costs down back to you as suppliers or somehow pass them onto the consumers, or I guess get governments to subsidise the difference, which eventually comes back to consumers in forms of taxes. But I’m a little sceptical that passengers actually are going to go out of their way and make that choice as opposed to sort of just expecting that airlines are, and the industry is doing the right thing and moving in this direction. And that’s part of, you know, table stakes at this point.”

Sandiford responded: “Well, I agree with you a hundred percent on your scepticism. However, one of the things that I always say is, you know, if, if I’m fishing, the more hooks I get into the fish, the more likely I am to reel them in, right? So, the sustainability attributes of the cabin for the flying public is just another hook that I’m trying to get in, along with the frequent flyer programmes, along with the destinations that are served along with the price of the ticket and so forth. So, it’s all building an overall value proposition and a brand image for the airline in terms of the sustainable attributes that they’re bringing to the marketplace, right? So, they have to leverage that in terms of their branding. If they don’t, it still doesn’t diminish the fact that we as an industry need to go to a net zero focus in terms of the supply of materials for an airline cabin interior.”

As mentioned at the beginning of this article, these insightful comments are just a small number of the highlights from the roundtable discussion, which features a wealth of thought-provoking discussion in the full-length video recording which is available here.